Emergency: TSMC 12-inch fab has outbreaks of industrial pollution accident in succession together with foundry orders loss(1)

Semiconductor major maker TSMC has outbreaks of industrial accident again. There are two pollution incidents, a big and a small according to seriousness, which both occur in Nanke fab 14. Affected 12/16nm wafers are over ten thousand. Clients such as Hisilicon, MTK, Nvidia are pedicted to be affected, while TSMC responds its first quarter profit outlook won’t be affected with minimizing loss.

TSMC Nanke fab 14 has outbreaks of two “pollution cases” on 28. From the morning on, iron ion is said to be polluted in forepart etch at first. And then photoresisit is also said to be polluted which affects more than ten thousand. Rumours surrounding the market while TSMC hasn’t clarified whole event.

Two “pollution” cases break out in same area in one day

As terminal electronic products getting smaller, semiconductor components are shrinking which results test specification is getting more harsh. According to inductry sources, forepart etch iron ion pollution on 28 is because it doesn’t pass internal testing procedure of TSMC. However, the issue is solved immediately. Only hundreds of wafers are affected which is significant that won’t make a great difference.

Quickly, an outbreak of second “case” in fab 14 occurs on the same day. According to industrial source, its photoresist pollution results in some online wafers in this plant scrap, which is because forepart transistor pollution may cause abnormal electric leakage of wafer and then affect production yeild and reliability.

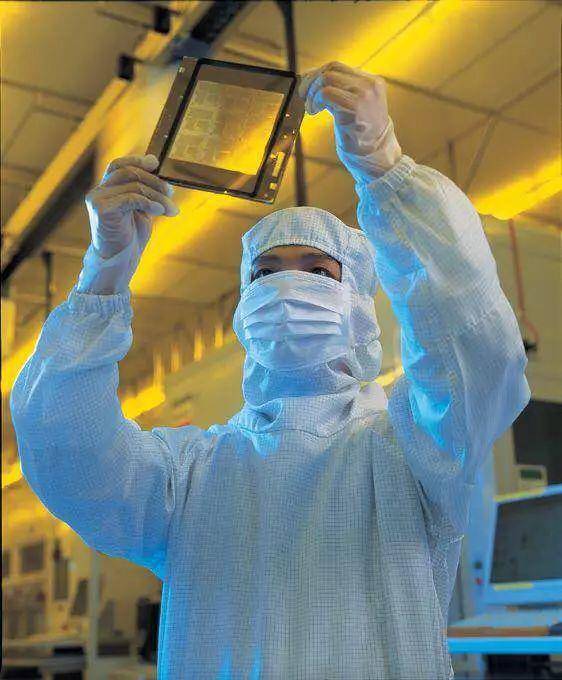

Figure TSMC fab 14 has outbreaks of pollution incident, so employees of this factory are told to come back from their vacation to do comprehensive review of the factory.

Due to error chemical raw material against original specification, output wafer yeild is affected said by TSMC, who is clarifying cause of this issue and communicating with clients of details and subsequent processing.

TSMC emphasizes again that affected wafers will be recovered in the first quarter, even the rest part will be recovered in the second quarter. On basis of current schedule it won’t affect profit outlooks of the first quarter.

According to sources, Japanese photoresist suppliers of TSMC including ShinEtsu, JSR and Dow Electronic Materials, but photoresist raw material used in fab 14 is not from Japanese supplier. Its affected capacity may be over ten thousnad.

Most employees in TSMC Nanke fab 14 have been told to come back from their vacation to focus on making detection.

If final test result shows this batch of chemical raw material having problem, TSMC can claim for compensation from suppliers. However, if the problem is due to TSMC adopting wrong device parameters, the problem will be more complex, said by supply chian.

TSMC Nanke fab 14 is a town for 12/16nm technology, whose major clients including Hisilicon, MTK and Nvidia. Although TSMC has gotten into high-end era, 12/16nm is always hot so it is the mainstay which replaces 28nm to be a significant era.

What is importance of 12/16nm among TSMC’s revenue? It accounts for 25% of the first and second quarters revenue in 2018(a small part of which is 20nm). Proportion of 16nm and 20nm declines to 21% in the fourth quarter of 2018, because high price 7nm process begins mass production which dilutes 16nm process proportion of revenue.