The first Chinese 5nm plasma chromatography has passed validation of TSMC to be the world’s first 5nm process

The media exploded with the news of Chinese ultraviolet super resolution SP lithography machine few days ago. The machine, which realizes a 22nm maximum resolution of single exposure by 365nm wavelength, breaks limits of traditional lithographic resolution caused by light wavelength and traditional line pattern of lens’ numerical aperture. The equipment is worth between $1.45 million and $2.9 million which is less than 2% of EUV. Although the SP lithography machine breakthrough is significant, it can’t replace the current lithography machine because its limitation of special technologies which is not fit for mass production. Semiconductor production needs other equipment besides the lithographic, such as etching machine. The 5nm plasma chromatography developed by AMEC which has passed the validation of TMSC will be use in the first 5nm process.

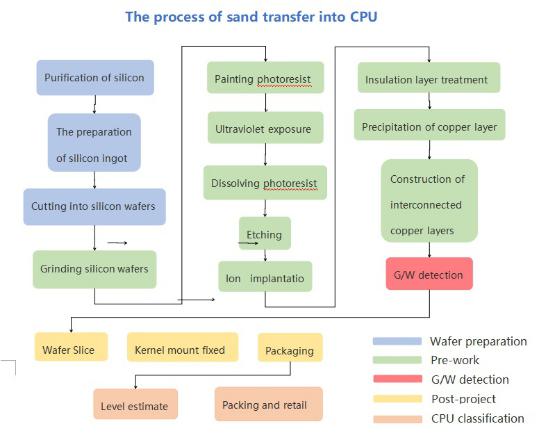

Lithography machine is the key role during the production of semiconductor, so it has a high exposure in media. However, besides core photoetching etching is also a important process among the hundreds of semiconductor processes. Immerse wafer into groove containing etching agentia, then the exposed part of wafer will be dissolved with the rest being protected by photoresist.

After the introduction of background, the news of 5 nm etching machine developed by AMEC has already been reported on CCTV2 by itself in March, 11th, 2017. Now the etching machine which finally passes the validation of TSMC can be used in 5nm production line. But the 5nm process of TSMC which is being developed will have trail production in next year and mass production at least in 2020.

Considering the 5nm advanced process of the machine, its news may explode the media. Actually, the 5nm has nothing to do with the etching machine which doesn’t determine semiconductor process. It is not easy for AMEC to get into supply chain of TSMC together with other semiconductor improvements, which will be beneficial to improving Chinese semiconductor level.